Products

Introduction

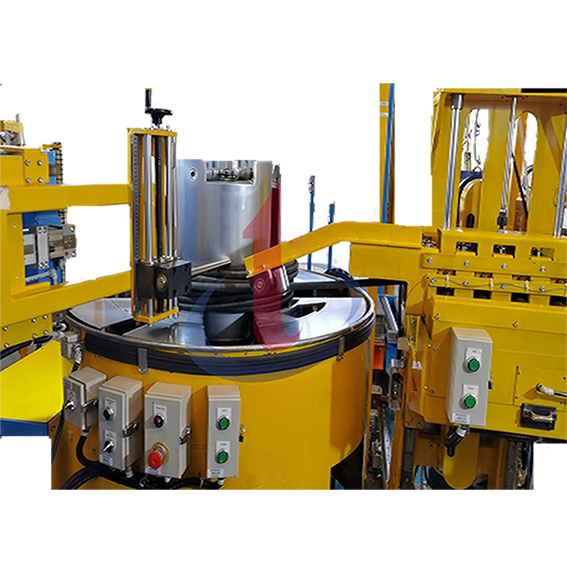

This product is installed on the top of the belt of the forming machine, and uses the 3D measurement technology to measure the width of the belt and the tread, the detection, tracking and alarm of the defect, so as to provide the data reference for the quality control of the product.

The main functions are as follows:

1. Real-time detection of multi clock defects with beam and tread can be detected, including but not limited to common defects such as continuous connection, overlap, fault, wrong side, center offset and so on.

2. test data and tire number corresponding preservation, to achieve problem tracking;

3. visual output of test data (graphics and forms), providing data support for quality management.

Advantages

1. Using 3D measurement technology, high detection precision;

2. Installation and operation is simple and has no effect on the production process of crude oil.

3. No contact detection, no damage to the product surface and no pollution.

4. The system has a wide range of applications and can detect multi tire specifications.

Categories

Latest News

Contact Us

Contact: Miss Kou

Phone: 15165321981

Tel: 0532-68862234

Add: No.1 Xiangling Road, Laoshan District, Qingdao, P.R.China