Products

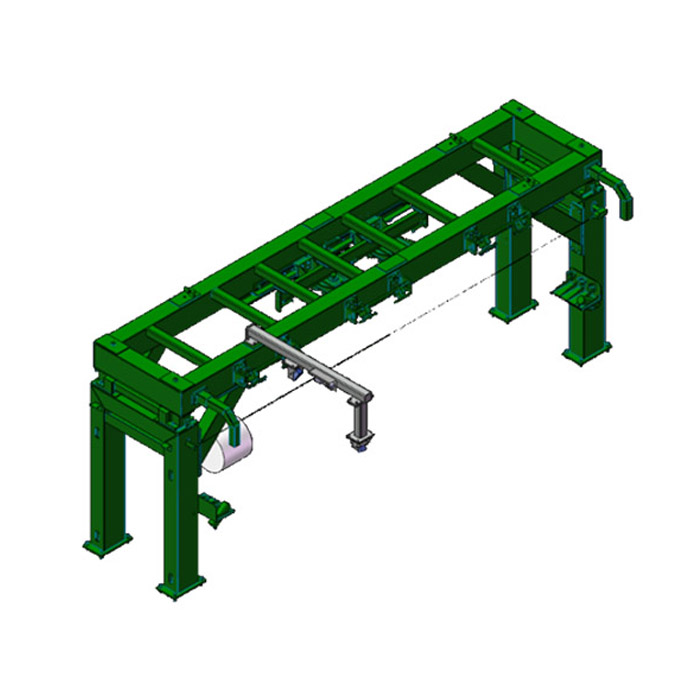

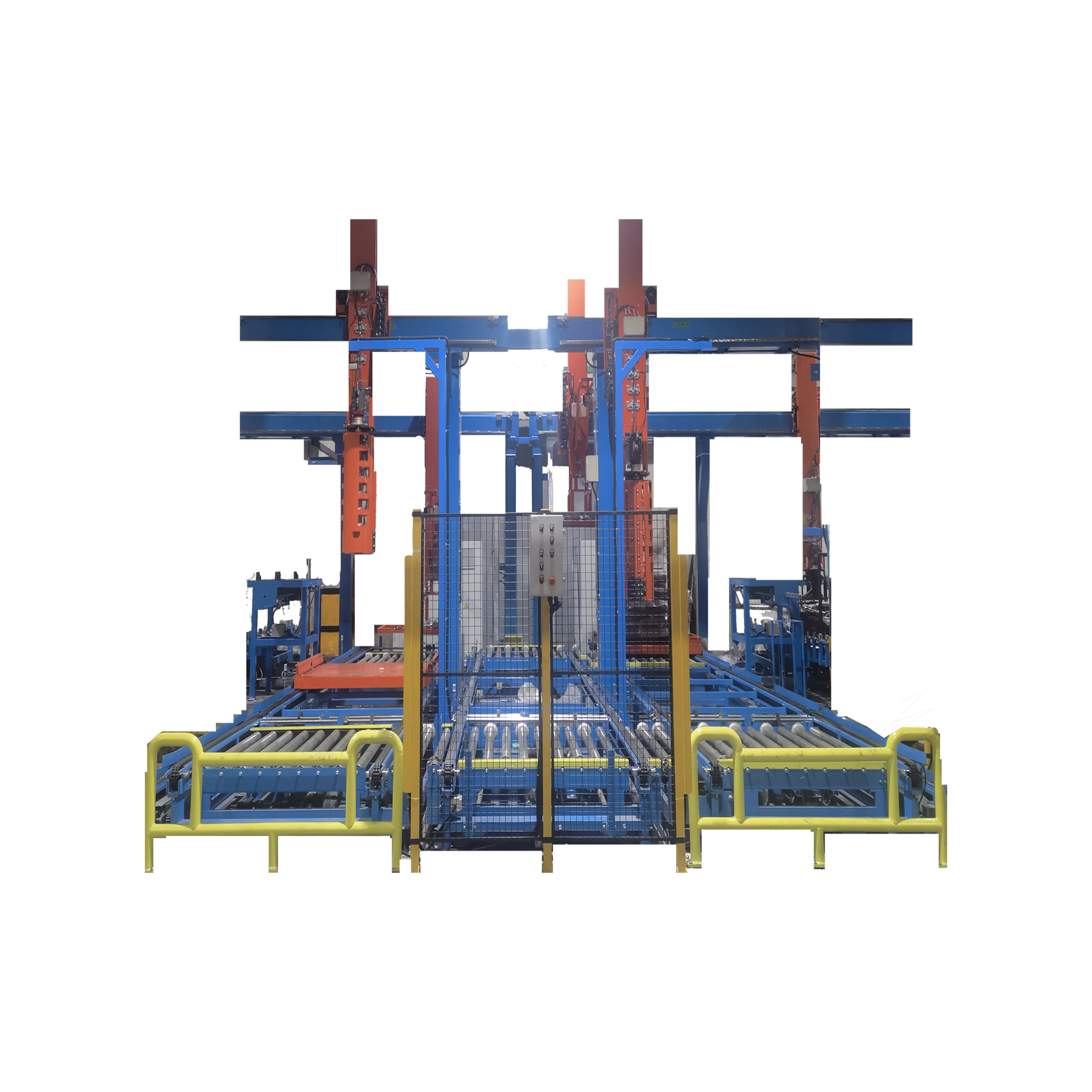

The equipment is used to realize the automatic loading and unloading of the rubber plug vulcanizing machine, including the functions of the incoming plastic pile stacking and single pile of glue transfer, single piece of raw glue and separation of the septal layer, the recovery of the spacer, vulcanizing machine feeding, film cooling, spraying release agent, vulcanizing machine material, vulcanizing film waste edge cutting, vulcanizing film cutting into small pieces, finished vulcanizing film packing. In order to realize the vulcanizing machine accurate loading and unloading and vulcanizing film cutting precision and design a deviation correction positioning device, and can judge whether there is a waste edge residual in the vulcanizing mold after blanking. The equipment adopts advanced machine vision technology and manipulator cooperation, completely replace manual, unmanned operation, is the first product in China.

Advantages

1. Suitable for a variety of models: single - mode vulcanizing machine, double - mode vulcanizing machine

2. High degree of automation, replacing manual work;

3. Automatic collection of debris dust to avoid environmental pollution;

Micro-lubrication cooling system, avoid high cutting temperature rise, ensure cutting quality;

4. Modular tooling design modular, to achieve the rapid replacement of rubber strip specifications and cutting tools.

Intelligent production management system,to achieve production information and tool life management.

Categories

Latest News

Contact Us

Contact: Miss Kou

Phone: 15165321981

Tel: 0532-68862234

Add: No.1 Xiangling Road, Laoshan District, Qingdao, P.R.China